Your external production partner,

with experience from 100+ projects.

Global production partner with over 25 years of experience in production.

With a global production partner that is ISO 9001:2015 certified, you get a partner with extensive experience producing products and parts while ensuring high quality and efficient quality control measures.

We have built our production lines with complete flexibility so you can have your production done how you want.

Our assembly facilities in Vejle, Denmark, allow your products to be assembled locally. They are located at our Danish office, ensuring quick production setup and quality assurance.

Our production and assembly facilities in China allow you to produce your products at lower costs without compromising on quality and delivery reliability.

Global producer - Local collaboration partner.

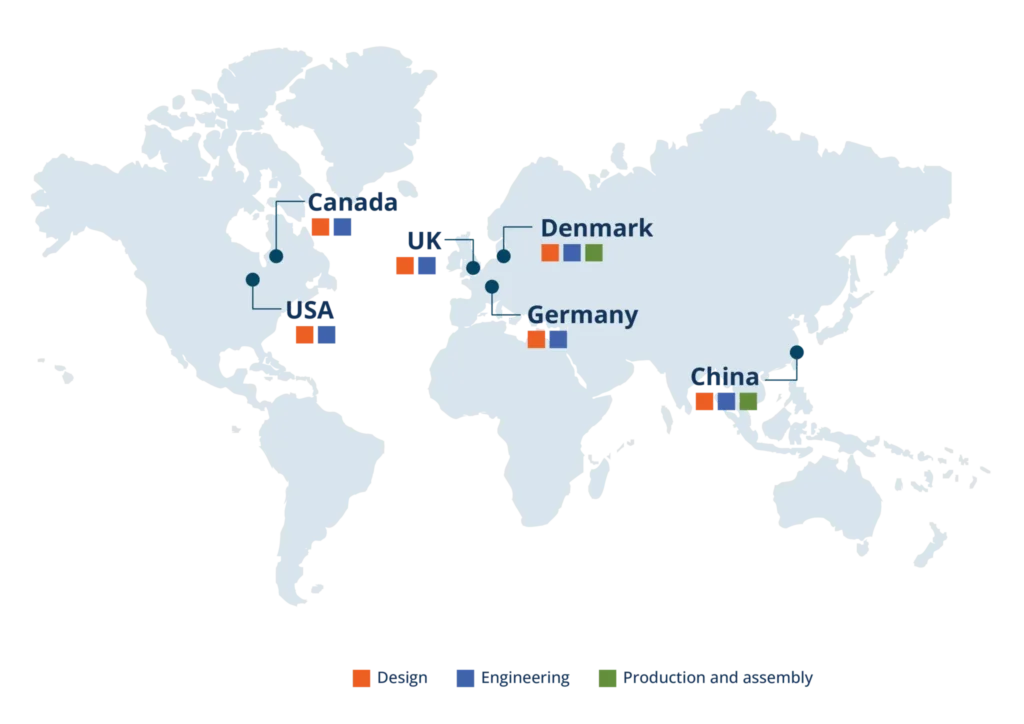

With a presence in 6 countries, we’re where you are.

Whether you’re starting in Denmark and looking to expand your market or selling primarily overseas, we offer flexible delivery solutions and local contacts.

Quality - because we take the time.

That's why we've RECEIVED THE CERTIFICATION THAT PROVES we do quality properly

The ISO 9001:2015 certification ensures that we review and document our products, providing quality-approved products that meet agreed requirements and are delivered on time.

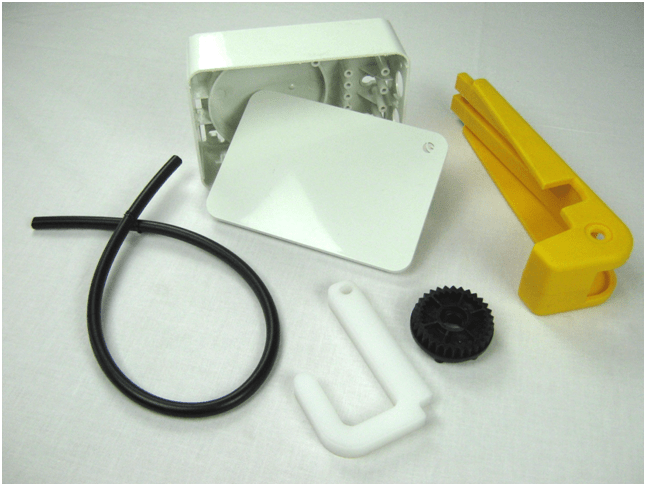

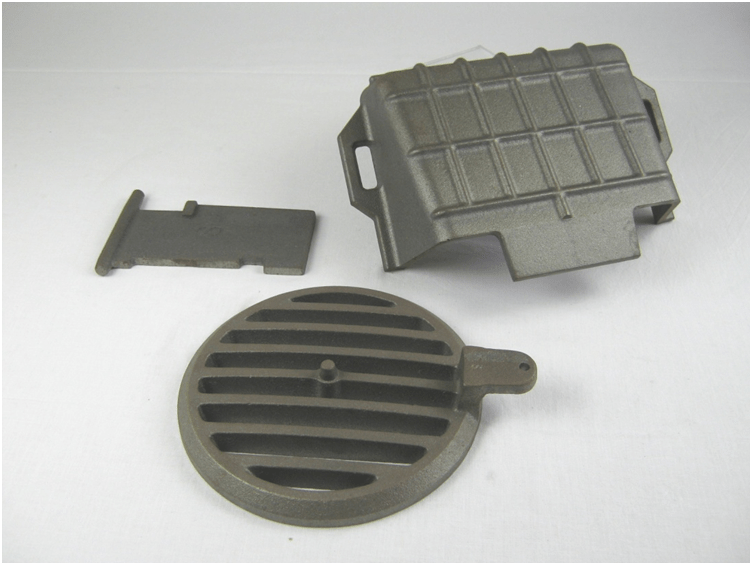

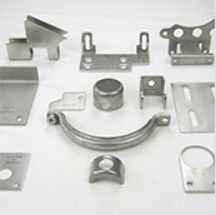

What manufacturing process should we use for your product?

Milling? Injection moulding? Machining? Welding? Deep drawing? Extrusion? Punching? Thermoforming?

We have extensive experience with most production processes, ensuring you a production partner who understands the production method.

With over 25 years of experience producing everything from semi-finished products to complete products, we know what it takes to make a complete product and understand your requirements for your products and parts.

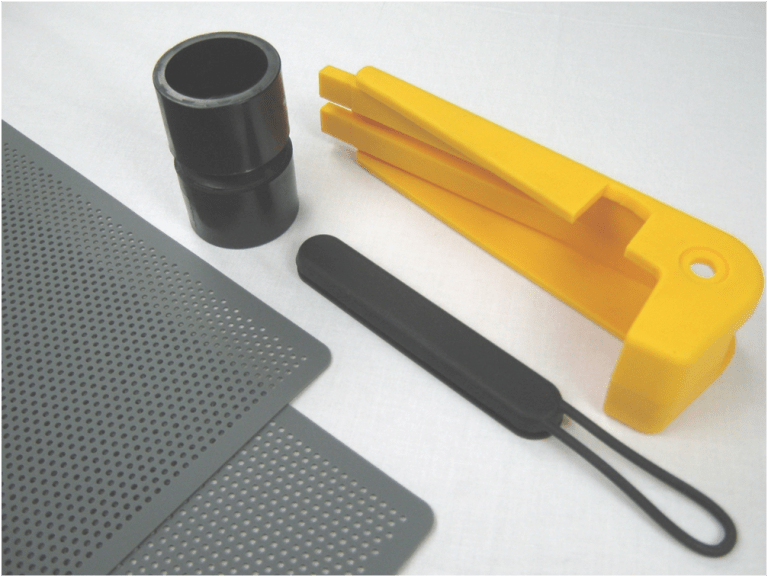

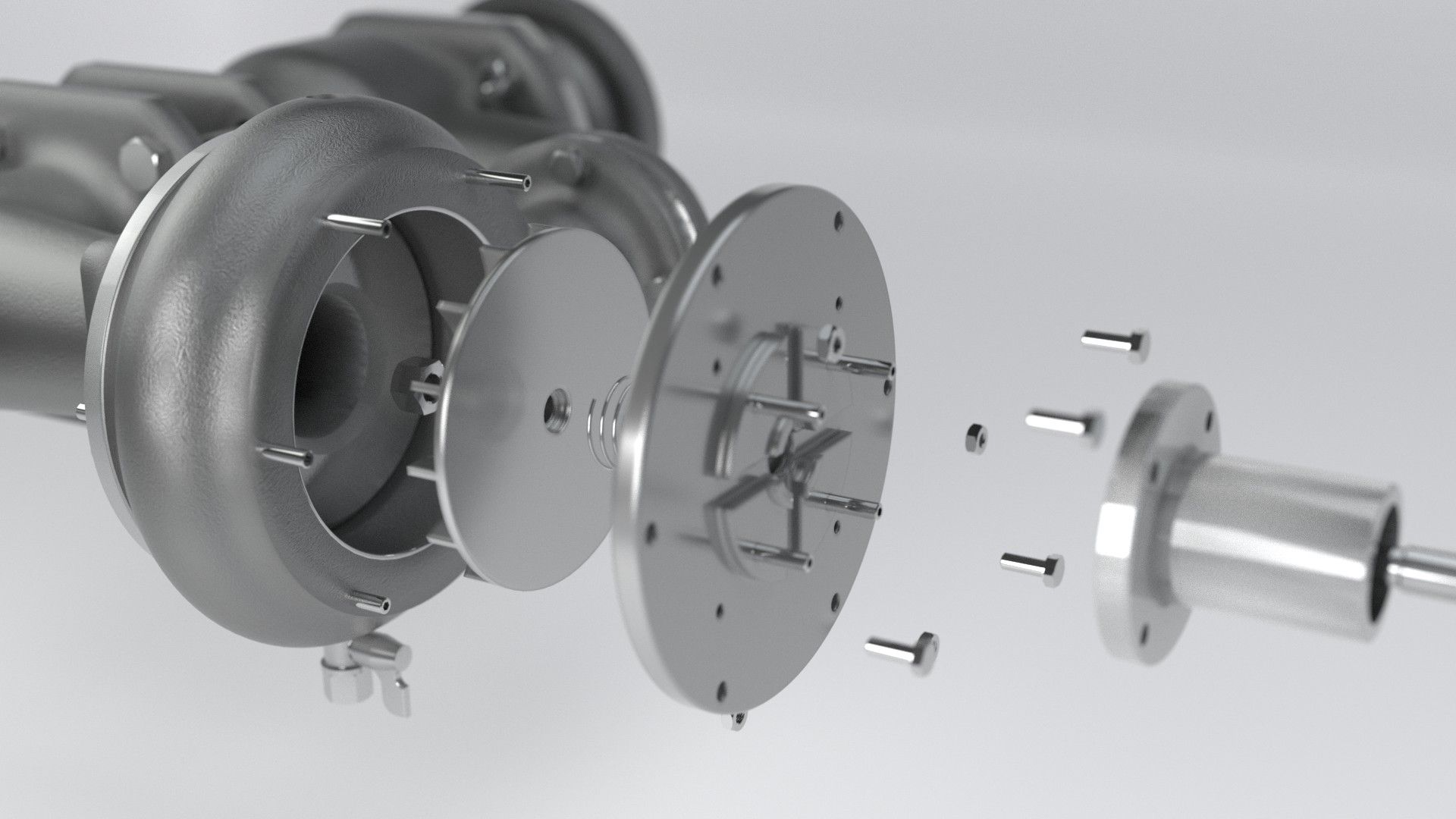

Here, you can see some of the previous items we have produced using various production methods.

Fasterholt

Need to outsource YOUR PRODUCTION?

There are advantages and disadvantages to outsourcing production. Here are the top 3 advantages and disadvantages of choosing an external supplier to produce your products.

Benefits

Cost savings

One of the most significant advantages of outsourcing is the possibility of saving time and resources.

We have a production setup that can help you reduce your production costs. With our solid network of subcontractors in China, we can further reduce your costs.

Overall, this helps to reduce your production costs and make you more competitive with increased profits.

Focus on core competencies

By outsourcing production, you can focus your resources on core competencies such as product development, marketing, sales, and customer care.

Let us handle the production and quality control of your products so that you can improve your products, expand your market share, optimise your sales channels, and enhance customer service levels.

Access to expertise and resources.

Working with a production partner gives you access to a skilled team of designers, engineers, and production experts.

This shortens product development time, enhances quality, and enables cutting-edge production methods, ensuring you receive superior products.

Disadvantages

Loss of control

When outsourcing production, it can be challenging to maintain the same level of direct control over the production process and quality control.

This can lead to concerns about product quality, schedules, and compliance with standards. However, we do our best to ensure quality and remember that specific challenges may arise when maintaining the same level of control as with internal production.

To mitigate this disadvantage, we assign several advisors to your company so that you always have direct contact with those working on your project.

Risk of communication problems.

Language barriers, time zone differences, and cultural disparities can create communication problems between your company and your outsourcing partner. This can result in misunderstandings, delays, and quality issues.

Therefore, it is essential to have a production partner who understands what information is necessary to achieve an optimal development process and ensure the quality of ongoing deliveries.

Dependency on third parties.

When you outsource, you become highly dependent on your outsourcing partners. If a partner experiences problems or failures, it can negatively impact your own production and supply chain.

Although our track record is reliable, it is essential to understand that this dependence exists and that there may be risks associated with it.

Guide to outsourcing production.

It will guide you through the process and ensure you get the most out of the collaboration.

Flexible delivery methods

Direct delivery, vendor-managed inventory (VMI), and consignment inventory.

We offer a wide range of logistic solutions to deliver your products as needed, allowing you to optimise your production or sales process.